About SCFE

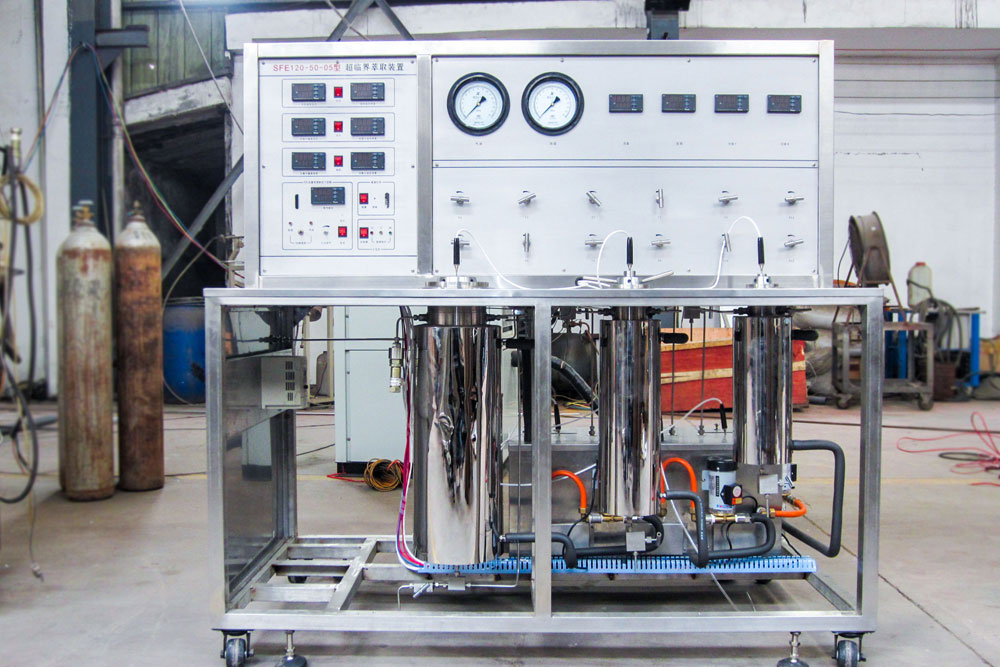

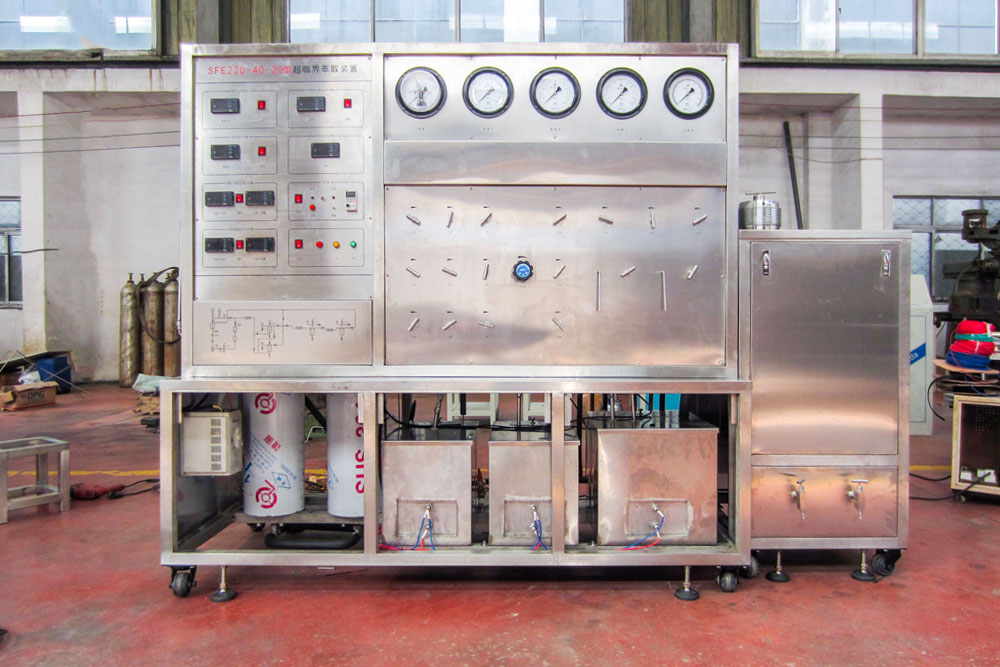

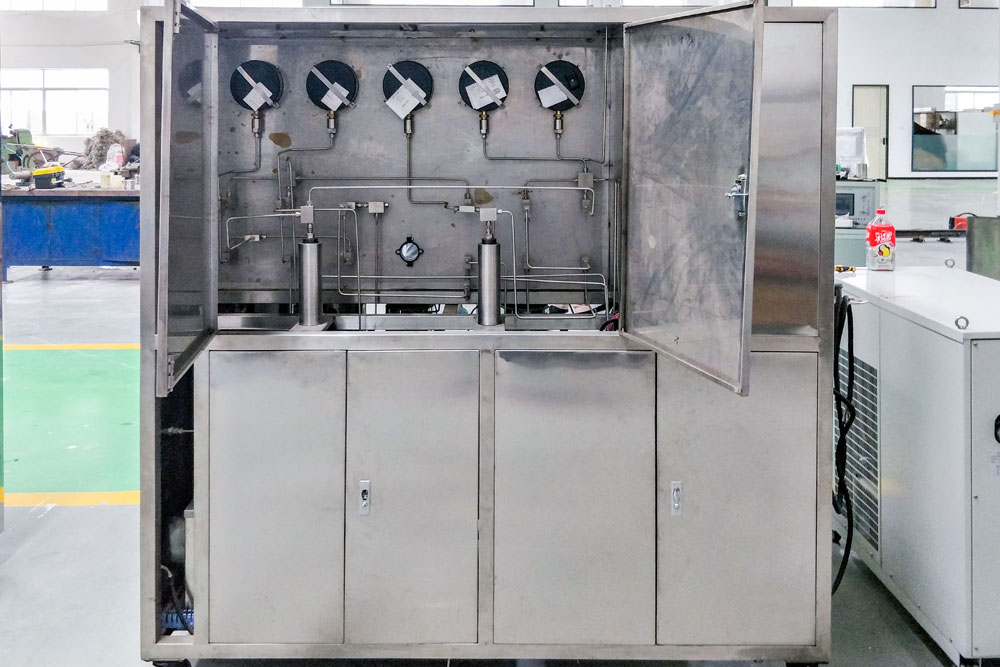

Supercritical fluid extraction is a new and advanced separation technology in modern chemical industry, which refers to a process during which solute diffuses in solvent when solvent and raw material are in full contact in extractor under high pressure and proper temperature. Then the solute will be separated from the solvent in separator by changing operating conditions. Recently supercritical fluid extraction technology has been developed in a quick pace home and abroad and applied in industrial scale on humulus lupulus, spices, Chinese herbal medicines, oils, petrochemistry, health food, etc.

Why Choose Us?

- Provider of over 100 sets of SFE systems

- Aerospace brand with military quality

- R&D supported by National Engineering Centre

- Core parts manufactured by us with our own patens

- High-precision automatic control

- Saving you 1/3 power consumption for same capacity

- Saving you 2/3 investment for same capacity

- Training, process development and optimization service available

| No. | Type | Specification | Pressure | Flow | Area | Height | Capacity of raw material |

| 1 | 5L+1L | two extractors two separators | 500bar | 60L/H | 10 m2 | 2.5 m | testing purpose |

| 2 | 10L*2 | two extractors two separators | 500bar | 100L/H | 10 m2 | 3 m | 10 to 20 kg |

| 3 | 25LX2 | two extractors two separators | 400bar ~ 500bar | 300L/H | 20 m2 | 4.5 m | 50 to 150 kg |

| 4 | 50LX3 | two extractors two separators | 400bar ~ 500bar | 600L/H | 80 m2 | 5.5 m | 0.1 to 0.3 ton |

| 5 | 100LX3 | two extractors two separators | 300bar ~ 500bar | 1000L/H | 130 m2 | 7 m | 0.2 to 0.6 ton |

| 6 | 200LX3 | three extractors two separators | 300bar ~ 500bar | 1500L/H | 200 m2 | 8.5 m | 0.5 to 1.2 ton |

| 7 | 300LX3 | three extractors two separators | 300bar ~ 500bar | 2500L/H | 300 m2 | 9 m | 0.7 to 2 ton |

| 8 | 400LX3 | three extractors two separators | 300bar ~ 500bar | 3500L/H | 400 m2 | 9.5 m | 1 to 2.5 ton |

| 9 | 500LX3 | three extractors two separators | 300bar ~ 500bar | 4000L/H | 450 m2 | 10 m | 1 to 3 ton |

| 10 | 600LX3 | three extractors two separators | 300bar ~ 500bar | 4000L/H | 500 m2 | 10 m | 1.5 to 3.5 ton |

| 11 | 800LX3 | three extractors two separators | 300bar ~ 500bar | 6000L/H | 540 m2 | 12 m | 2.5 to 4.5 ton |

| 12 | 1000LX3 | three extractors two separators | 300bar ~ 500bar | 8000L/H | 540 m2 | 14 m | 3 to 6 ton |

| 13 | 1500LX3 | three extractors two separators | 300bar ~ 500bar | 8000L/H | 600 m2 | 14 m | 3.5 to 8 ton |

| 14 | 2000LX3 | three extractors two separators | 300bar ~ 500bar | 10000L/H | 600 m2 | 16 m | 5 to 12 ton |

| 15 | 3500LX3 | three extractors two separators | 300bar ~ 500bar | 16000L/H | 700 m2 | 16 m |